John Rannoch Foods

Armagard Aids Data Capture On The Shop Floor For John Rannoch Foods

About John Rannoch Foods Limited

With premises located on 200 acres of parkland at Haughey Park close to Stowmarket, Suffolk, John Rannoch Foods Limited - part of the 2 Sisters Food Group - specialises in poultry processing.

The independent, private company is a major supplier for Marks and Spencer and other major retailers, including Whitbread. John Rannoch operates its own transport fleet with some 20 deliveries each day, with vehicles shuttling between the factory and customers' regional distribution centres.

The Challenge

John Rannoch Foods sought to upgrade its manual data distribution and recording processes, which involved a lot of paperwork, across its entire factory network. To do this, they wanted to install computer systems on the shop floor, but this was no easy task in an environment as unforgiving as a meat processing plant.

They required a solution that could cope in humid, wet conditions. Equally, as a food production facility, any solution needed to be easy to clean in order to maintain hygiene standards.

The Solution

John Rannoch foods opted to install 35 Armagard terminals across its facilities. Each terminal is housed within a stainless steel enclosure, designed specifically to meet the IP67 specification for hostile, wet environments.

A separate enclosure is used to house a printer for bar code labels, which enables John Rannoch Foods to use any mainstream label printer on the market.

Information systems manager for John Rannoch Foods, Paul Nix, said: “By keeping this option open we have been able to shop around for suitable but less expensive off-the-shelf printers. We hold spare units in stock and they are easily replaced without taking the terminal out of service.”

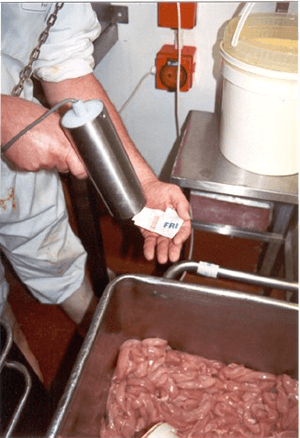

The bar code labels are a crucial part of John Rannoch's production control system and the majority of the PC terminals are equipped with Armagard, bar code laser scanners.

The Results

Every item moving in and out of the factory is now easily recorded, either by scanning the bar code label for identification, or by printing a new label to confirm the completion of a production process.

The bar code provides traceability for every product and ingredient shipped by the factory, together with the order reference numbers and processing dates.

The newly installed computer terminals play an important role in scheduling orders, setting priorities and the procurement of raw materials. Historically, this involved a high level of manual labour for the printing and distribution of computer schedules and completion of manual records for each batch process.

The computer terminals are being used to present the production schedule at every workstation. Instead of staff having to manually record items they have used, they can scan the information from the bar code label.

Equally, instead of recording what they have made, they print a label and attach it to the item to pass the information on through the system.

Return on investment

Paul Nix estimates that the computer terminals save the company around 2% on labour costs. With a total workforce of 1,000 people, this is equivalent to between £330K to £500K per year.

“Effectively this means we have achieved a positive return on our investment, recovering the cost of the hardware in less than nine months,” Paul Nix said.

Processing each customer order takes up to 48 hours for the delivery of finished products. The process involves some 8 to 10 stages from, killing the chicken through to cutting up, flavouring, cooking, packing and despatch.

Paul Nix said: “We are operating in a very dynamic market where order requirements can change daily. Since all our products and the ingredients we use, such as cream, have a limited shelf life, it is essential that we have complete visibility of our production status to control stock and the procurement of materials.”

“The new system enables us to minimise waste, deploy our workforce more efficiently and therefore, fulfil our customer orders more efficiently,” Mr Nix added.

Fewer mistakes and reduced waste

Since installing the new computer terminals, John Rannoch Limited has highlighted a more efficient process for the procurement of raw materials. Mr Nix commented: “Because we are making fewer errors our stock consumption has reduced by 80 pallets in the last three months.”

“There has also been a corresponding reduction in waste. Traditionally waste was costing us around five percent of turnover. Waste comes in different forms, such as over delivery to the customer, or by the disposal of surplus materials left over because of the over ordering of key ingredients,” Mr Nix said.