How to Run Cables Into An Industrial Computer Enclosure

During the design phase of industrial computer enclosures, plenty of planning goes into building a system that protects computer hardware and any peripherals. However, a common question asked by end-users, is 'how do we power electronics inside a sealed enclosure?'

Industrial computer enclosures with an industry standard rating of IP56 (NEMA 4 in North America) or more are classed as 'fully-sealed', waterproof units, which will not include a traditional split panel for feeding cables into the enclosure.

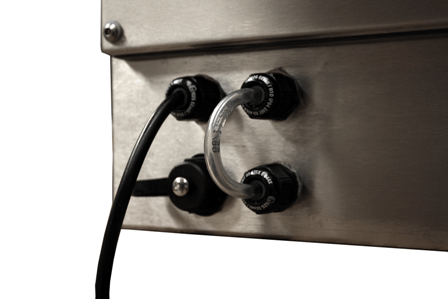

Instead, most enclosure systems are fitted with cable entry glands that will maintain a seal, while providing a clean, safe entry point for cabling to reach computer equipment. There are varying types of cable gland available to suit specific enclosure applications.

When in the market for an industrial computer enclosure, industrial buyers should bear these five things in mind for feeding cables into the unit:

1. Point of Entry

Ideally, particularly in facilities where water is present, you should insert cables into enclosures from below if the system is wall-mounted. For modular, freestanding systems, cabling should run downwards because feeding wires in from above will lead to water penetration with droplets flowing down cables.

2. Cable Diameters

The type of cable gland required for your enclosure application depends on the width of the wiring you're feeding into the unit. Sealed cable glands are available in multiple sizes for different cable diameters. For example, formats exist that allow several wires - ranging from 0.3” ~ 1.5” - to pass through the same gland.

Glands are manufactured using different materials, including:

- Aluminium

- Brass

- Plastic

- Rubber

- Steel

To determine the ideal cable gland configuration for your specific enclosure application, consult an enclosure expert.

3. Open Version Cable Glands

Finding the right cable gland - particularly for pre-terminated cables - can be challenging. It's likely that the end of the plug will be significantly larger than the cable width.

Ideally, you should choose a cable gland that is permeable because this allows for quick installation of pre-terminated cables with connectors already attached, while minimising disruption to the operational function of your computer enclosure system.

4. System Changes and Upgrades

Computer technology is constantly changing, and will continue to develop at an accelerated rate. On the other hand, a quality computer enclosure will last several years… decades in some cases. You're more likely to replace or upgrade computer hardware a few times before your manufacturing facility needs a new enclosure.

With that in mind, opting for a flexible cable gland configuration will allow for system repairs, replacement or upgrades… minus extensive downtime. When consulting an enclosure expert, discuss designs that give you versatility.

5. Safety

Health and safety is paramount on the manufacturing floor, and in a golden age of computer use across industrial facilities, computer cabling represents a trip hazard. Prior to the installation of your enclosure, it's worth assessing your options in terms of positioning, factoring in the concealment of cables out of harm's way.

Operational performance and reliability are central to an enclosure installation. Poor planning for cable entry could compromise the protection of your computer hardware, particularly in wet and humid environments. If you haven't taken the necessary precautions to seal cable entry points, water WILL find a way in.

For industry-leading support, contact Armagard to discuss your industrial computer application. Call +44 (0)121 608 7226 or email sales@armagard.com. Alternatively, complete our quick contact form with a few details about your requirements and we'll get in touch.